The Value of Value Engineering

Monday 23rd August 2021

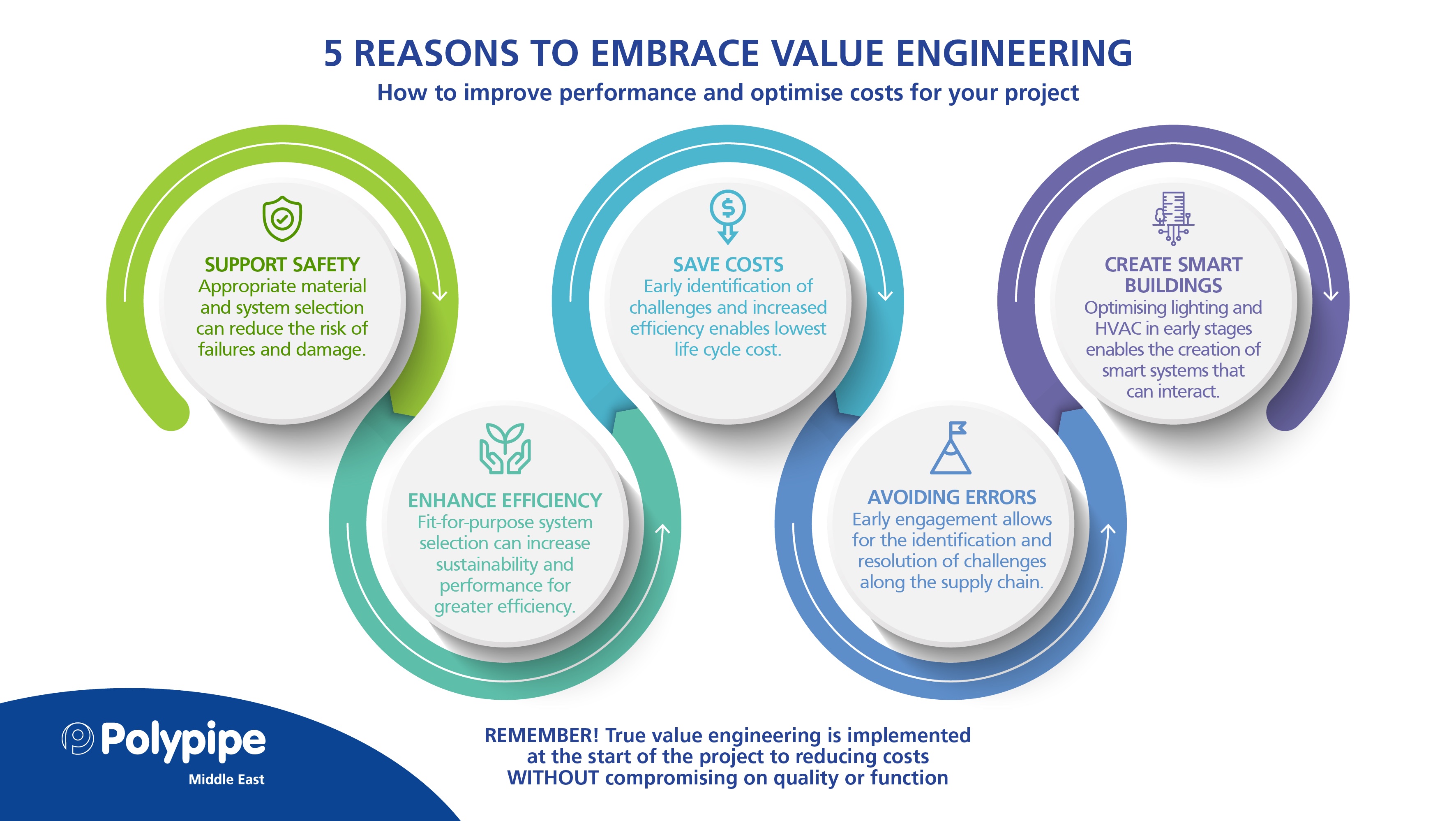

If you’re operating in the construction and manufacturing industry, chances are you’ve heard the term ‘value engineering’. Some may define it as reducing costs, while others say it’s about adding value to the project - in reality, it’s both.

In any market, the basic principle of value engineering is to lower costs while maintaining or even improving functionality and quality.

As the regional construction industry increasingly focuses on sustainability, health and safety, value engineering can play a key role in creating more resilient spaces.

Let’s start by delving into the core tenets of value engineering...

What is value engineering?

Many great ideas are born as a response to a problem and value engineering is no different. An American engineer at General Electric pioneered the concept in order to alleviate the issues of labour shortages and the scarcity of raw materials following World War II. In response, he started looking into material substitutions and realised that certain materials were not only able to reduce costs, but they performed just as well, or even better, than the typical materials used. And so value engineering was born.

Lawrence D. Miles, the General Electric engineer, highlighted the idea that value is essentially the ratio of function to cost. Cutting costs is often considered the easiest approach to adding value, however is not the most sustainable. Reducing costs without acknowledging the consequences on performance often just leads to more challenges down the line.

Real value engineering emphasizes thorough analysis and evaluation of the production processes. The aim is to identify opportunities for improvement and optimise appropriately for an end result that delivers benefits on both cost and function.

In addition to financial benefits, value engineering is capable of delivering social and environmental benefits to transform your building. Here are a few ways value engineering can add value to your project.

Benefits of value engineering

1) Support Safety

Products and systems that perform as expected reduce the risk of failure and damage. Without failures or damages, occupants within a building are able to live safe, healthy and comfortable lives.

Furthermore, value engineering involves a profound assessment of materials, components and systems within a project. This approach allows for potential issues to be identified early on, enabling informed decisions for material and systems selection, thus further reducing the risk of future failures or damage.

2) Enhance Efficiency

Value engineering acknowledges the fact that a ‘one-size-fits-all’ rarely works well in construction. It supports the creation of fit-for-purpose solutions that recognise the customer’s requirements while still in the design stage. Not only does this improve performance in every application, it cuts out the need for adjustments or replacements later down the line.

Finding the right solutions for every purpose helps to increase sustainability and performance, producing an end result that works more efficiently.

3) Save Costs

Enhanced efficiency and appropriate material selection naturally result in lower expenditure. For example, designing and manufacturing with safety in mind saves on expenditure by reducing the chance of failures or need for maintenance. Enhancing efficiency also helps to cut out unnecessary costs such as components that are found to contribute very little to the function of the product.

Creating an overall high performing product that delivers on sustainability and durability ultimately helps to improve ROI for property owners.

4) Avoid Errors

Implementing value engineering at an early stage of the supply chain helps to identify potential issues before they have a chance to develop into something more serious. Resolving issues in their infancy is also much more cost effective than paying for redesign or changes as the project progresses.

Products developed in accordance with value engineering are designed for durability and longevity. This simultaneously lowers costs and increases sustainability, all while establishing a favourable reputation within the industry.

5) Create Smart Buildings

The principles of value engineering encourage the selection of smart and efficient systems. With this approach, creating smart buildings becomes a more cost-effective and feasible option. For example, optimising lighting and HVAC in early stages allows for smart system integration into our buildings.

In line with the UAE’s vision to create greener and smarter buildings, adopting a value engineering approach can help us realise regional sustainability initiatives.

Learn more about the why you should use value engineering for your next project:

Value Engineering and Sustainability

In our quest for sustainability, we essentially seek to meet the needs of the present, without compromising future generations’ ability to meet their own. A key aspect of sustainability is efficient resource management and waste reduction.

An increase in efficiency within the supply chain and production process correlates with an increase in sustainability. Selecting durable and recyclable materials can be more cost efficient and reduce the carbon footprint of a project to reduce life cycle costing and enhance efficiency.

This approach also enables the creation of green buildings and supports LEED ratings, contributing to increased overall sustainability in our cities.

In the regional construction industry, there are those that adopt a cost-first approach. It may be tempting to ‘cut corners’ and simply add value through lowering expenditure. However, compromising quality or function for price can just lead to more expenses down the line, thus negating the benefit of cutting costs in the first place.

The need for value engineering within the construction industry is becoming more and more pressing. Financial fragility is taking a hold. If the outdated industry methods are not addressed at a strategic level, things will continue to worsen. There has been little change thus far due to the concentration on short-term fixes; an unsustainable practice. Value engineering, instead, confronts problems at their roots.

For value engineering to truly work, it needs to be collaborative and collective. Every part of the supply chain must work towards a common goal: reducing costs while preserving or enhancing function and quality.

That’s why at Polypipe Middle East, we support modern methods of construction. We believe in the importance of accountability and ownership across the supply chain. Our approach focuses on building long term relationships and sharing our insights and information with the industry so you can become a part of our company. This approach, combined with a focus on productivity and repeatability in the manufacturing process, can help us overcome challenges in the construction industry.

At Polypipe Middle East, we have an expert team of engineers on-hand to help you with initial consultation. We innovate through collaboration to provide you with digital connectivity.

From low-rise to super high-rise, our solutions specifically recognise the demands of modern construction environments and work across all disciplines to help you get the job done. Contact us to find out more.

Tel: +971 (0) 4 518 3000

Email: middleeast@polypipe.com